Drying can be a production bottleneck in many types of industrial and commercial processes. When coatings are applied to a surface, a formation of a “skin” on the surface of a coating/ink during the drying process is always a big concern.

Spectra HE™ Ultra is about the efficiency of a drying process, with the emphasis on the word transfer rather than the word heat. Temperature is a secondary parameter in all of our Spectra HE™ Ultra equipment.

With Spectra HE™ Ultra acoustic drying technology, ultrasonic oscillating velocities of the air are 3-5 times more efficient than steady-state air velocity. This provides excellent micro-mechanical excitation of the molecules of moisture (water or solvent). The coefficients of heat and mass transfer are higher, which naturally allows liquids to be removed at accelerated rates.

When we deal with curing or cross-linking processes, heat is required to raise the temperature to required conditions needed for chemical reaction. With Spectra HE™ Ultra, only the ultrasonic air needs to be heated. Often the curing or cross-linking effect is achieved at a lower air temperature, a benefit of the more efficient drying.

More efficient drying, less kWh/ft2 is an additional benefit.

Acoustic energy allows more efficient transfer of moisture from the material being dried to the surrounding air, which is removed by an exhaust fan. Lower drying temperatures and less thermal energy are needed. That is why the energy efficiency of the Spectra HE™ Ultra ultrasonic drying technology is higher than that of most standard drying systems.

Many chemical formulations of coatings, inks, and adhesives were originally developed using solvents for optimal performance. Environmental, health, and internal product safety standards are set for the specific minimum residual solvent that a manufactured article can contain in various flexible, semi-rigid and rigid packaging applications. If the retained solvent level, that is measured by a gas chromatography (GC) method, cannot be met, the production rate needs to be reduced to meet required standards.

Installation of a Spectra HE™ Ultra drying module will help drastically reduce or eliminate retained solvent levels. Increased productivity is an important ROI factor for HTI printing and coating operation customers.

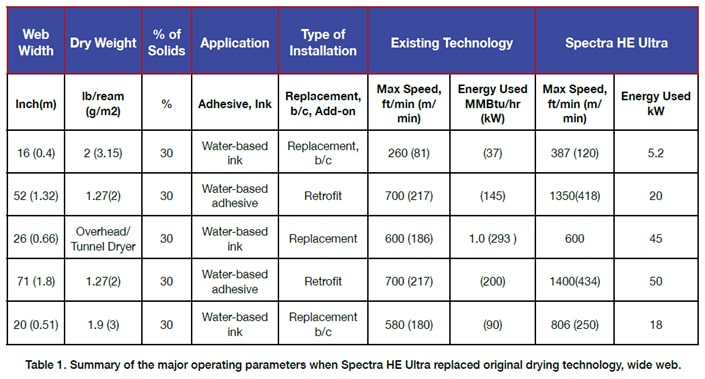

On the other hand, economic and environmental requirements will require a producer to transfer from standard solvent-based inks and coatings to new water-based products. Water-based formulation are much more difficult to dry, resulting in much slower production. HTI can regain “solvent line speeds” when using water-based inks and coatings.

The only moving part in our components is the wheel of an air supply blower. Since 2009 we have replaced only one blower and a couple of air heaters. Maintenance managers are typically our best friends! All of our systems are internet-ready and use major brands of control components. Our equipment is proudly made in the USA.

Where does this lead?

As a result, our Spectra HE™ Ultra drying systems successfully combine small footprint, high quality of production process, and the ability to offer higher throughput and energy efficiency in an extremely short footprint.

The technology has carefully expanded from drying paper webs to drying of inks and coatings, and drying and curing of water-based and solvent-based adhesives. It became a vital component in the utilization of biodegradable materials. It also carefully expanded from drying paper, inks and coatings to the food, pharmaceutical, and automotive industries.

Heat Technologies, Inc. holds 6 US and EU patents.

Wet weight of the coating on a this film is > than 50gsm.

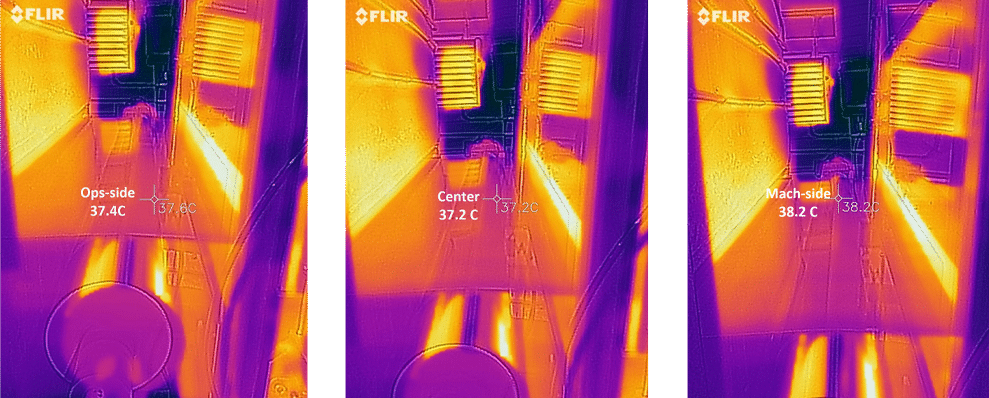

The temperature difference across the 1.7-meter wide web dryer is less than 1°C.