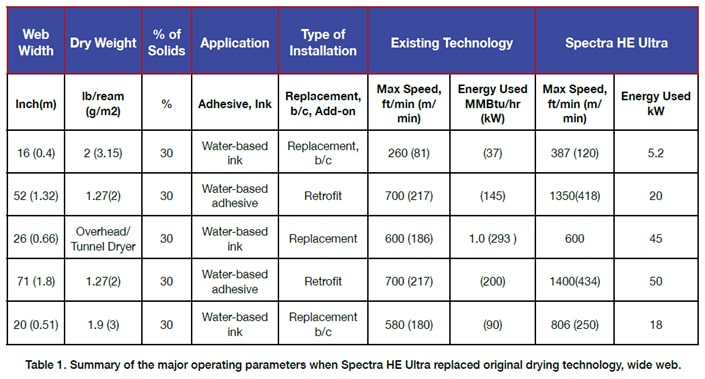

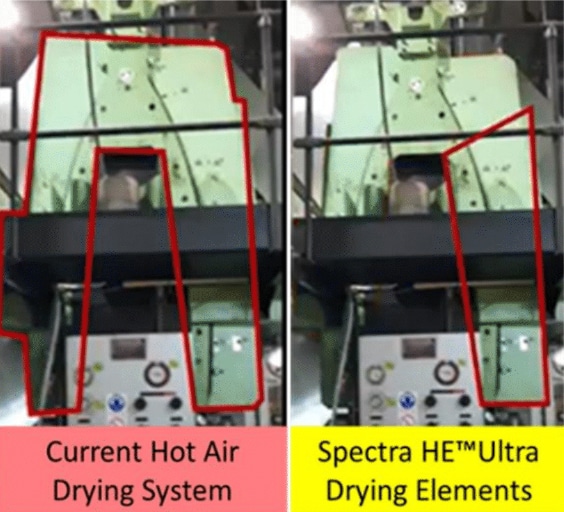

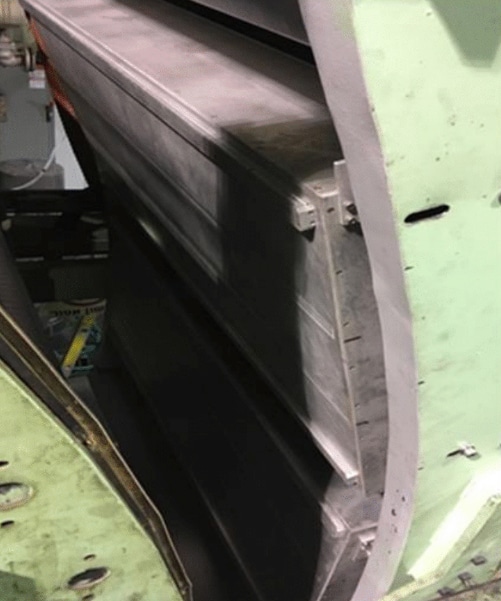

Here’s how HTI helped a specialty paper and film material producer address drying practices for increased efficiency with a single-stage Spectra HE Ultra dryer unit.

This customer wanted to streamline a process for printing with water-based inks at a heavier coat weight than they typically use. The standard business practice was to lay down two to three coats of ink at 100% coverage each to obtain the needed color saturation. Spectra HETM Ultra, HTI’s patented ultrasonic drying technology, offers an opportunity to improve the efficiency when drying water-based inks and coatings on rotogravure press operations.

Provide successful transfer of the coating operations from solvent based to water-based release liner formula and achieve the same quality, line speed (250 m/min), and production schedule of existing solvent-based coating operations.

An HTI customer that produces adhesive based products transferred its coating operations from solvent-based to water-based coatings. The formulation change was necessitated by strict environmental regulation. As a result, the throughput of the equipment was reduced by the factor of 3. This also resulted in the need to extend the production operations from 8 hour shifts/5 days/week originally to an extended 24 hr/ 6 days/ week schedule.

Results: