BEYOND THE BARRIERS OF PERFORMANCE THROUGH SOUND™

High Production Efficiency

Small Equipment Footprint

Reduced Energy Consumption

High Reliability

Reduced Emissions

Low Maintenance

BEYOND THE BARRIERS OF PERFORMANCE THROUGH SOUND™

High Production

Efficiency

Small Equipment

Footprint

Reduced Energy

Consumption

High

Reliability

Reduced

Emissions

Low

Maintenance

Advanced Thermal Solutions

Welcome to

Heat Technologies, Inc.PASSIONATE ABOUT THE BUSINESS OF HEAT AND MASS TRANSFER SINCE 1996!

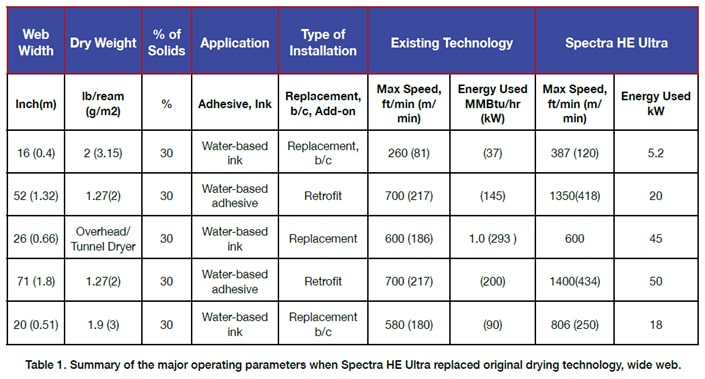

Spectra HE™ Ultra acoustic-ultrasonic drying systems can improve operational efficiency for a wide range of production operations whether it’s drying, or cooling, curing or lamination, and more. Commercial applications for paper and non-woven webs; and applying adhesives, inks, or coatings on papers or low-temperature thin films.

Our patented acoustic drying process emphasizes “transfer” rather than “heat” in the removal of liquids (water or solvents). It works by introducing ultrasonic vibrations into an air stream. This provides greater moisture-defusing efficiency.

3 Ways to deploy

Spectra

HEtm Ultra technology

Add-on

Spectra HE™ Ultra system is designed and strategically installed as an addition to an existing operation with the purpose to increased production throughput and/or reduction of energy consumption.

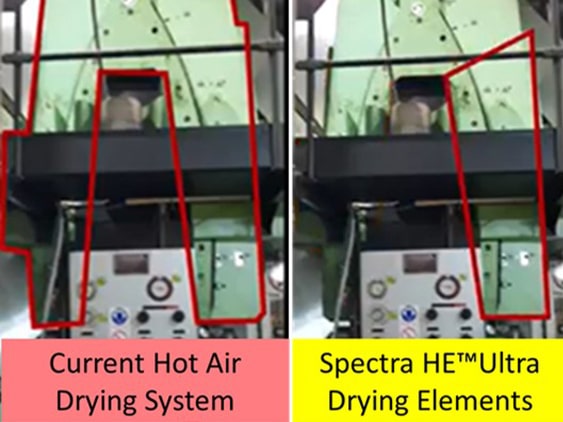

Replacement

Current drying system is removed and replaced with a custom-designed Spectra HE™ Ultra system is designed and installed on the existing frame.

New Installation

Spectra HE™ Ultra is the only heat and mass transfer technology used in production.