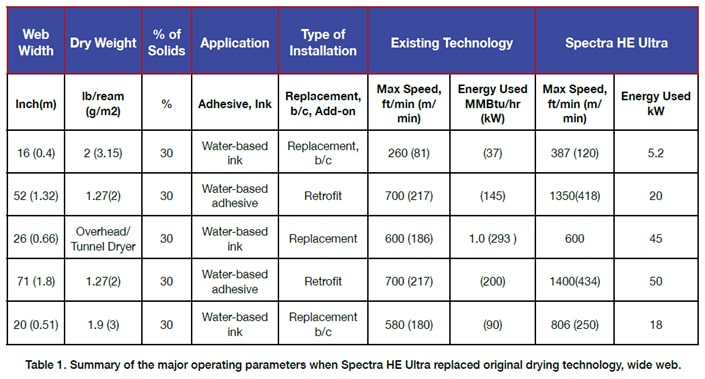

OBJECTIVE

Truly an add-on: its own heater, air supply blower, exhaust fan. Control panel integrated with the main control system.

HTI designed and built a booster Spectra HE™ Ultra system, which was installed in front of the drying station of a rotogravure press.

Achieved a 50% production increase with 25% of added energy and was installed in only a 3% increase of available footprint. The energy intensity (kW/m2) of the production process was reduced by 18%.

Dryer Length | Power (installed) | Line Speed | |

|---|---|---|---|

Current System | 50 ft

17 m | 586kW | 300 fpm

(100m/min) |

Acoustic System Add On | 1.5 ft

0.45 m | 115 kW | (150 m/min) |