Commercialization of Spectra HE™ Ultra Begins

In 2011, HTI actively promoted the new Spectra HE™ Ultra via trade conferences and technical presentations. Here are some highlights throughout the years. Here are some highlights throughout the years.

2011

AIMCAL Web Coating Conference in Reno, Nevada

At the AIMCAL Web Coating Conference in Reno, Nevada Gene Plavnik delivered a presentation on HTI’s Acoustic Technology. HTI, the pro vider of the Spectra HE™ technology for the converting industry, will discuss the science of acoustic energy, methods of application, and provide case studies of the technology in industrial practice. The presentation will focus on the use of Spectra for drying applications in narrow to wide web configurations. Attendees will gain an understanding of how Spectra Ultra HE delivers dramatically higher throughput rates with less energy than alternate drying technologies.

Flexo Gravure Int’l magazine – Drying at the Speed of Sound Dec 2011

An article presenting HTI’s technology was recently published in a German publication – Flexo Gravure Int’l magazine – Drying at the Speed of Sound. This has been a year of growth for HTI. We have put forth significant efforts to reach out to customers using seminars, magazine articles, open house and trade shows. HTI enters EU Market.

Society of Plastic Engineers 2011

Bernard Markel presented HTI’s Technology at the Society of Plastic Engineers 2011 International Polyolefins/FlexPack Conference in Hou ston, Texas. This conference has been in existance for 35 years. The presentation highlighted the application of the technology within the plastics industry…

2012

AWA Global Release Liner Industry Conference & Exhibition February 2012 Amsterdam, The Netherlands

Gene Plavnik presented HTI’s technology at these two conferences. Both venues provided, through expert presentations, panel discussions, and AWA exclusive market data, a complete overview of the current market environment, growth prospects and industry developments.

Heat Technologies Inc, at Drupa 2012

Heat Technologies, in conjunction with one of its European representatives can be found in Hall 5 Booth 5C44 at Drupa. Gene Plavnik and Tom Garlin are available to discuss the capabilities of the HTI’s Spectra Ultra Drying System for drying, heating, cooling and curing applica tions.

Acoustic Drying without Heating Substrate

Thermal image video showing the ability of the Spectra HE acoustic system to dry a heavy water based adhesive without imparting heat into the substrate. Unlike conventional solutions relying primarily on heated air, HTI’s acoustic mass transfer system is ideal for processing of temperature sensitive products. Watch the video on Youtube. (Need link) -the YouTube Video

Early Commercial Installations of Spectra HE Ultra 2012

Spectra HE Ultra heat and mass transfer system for one of the largest food products company

HTI has recently received an order for a 44″ (1.12 m) wide Spectra HE Ultra heat and mass transfer system to improve the operation of one of the world largest food product company. It is expected that this custom designed system will allow product throughput to be increased by 30%.

Jun 2012 62” wide dryer for a major US based packaging company

HTI recently received an order from a major US based packaging company for a 62” wide dryer. The unit is designed to increase line speed of the operation by 30%. It will have thermal capacity (installed) 115 kW and will replace a 250 kW infrared dryer….

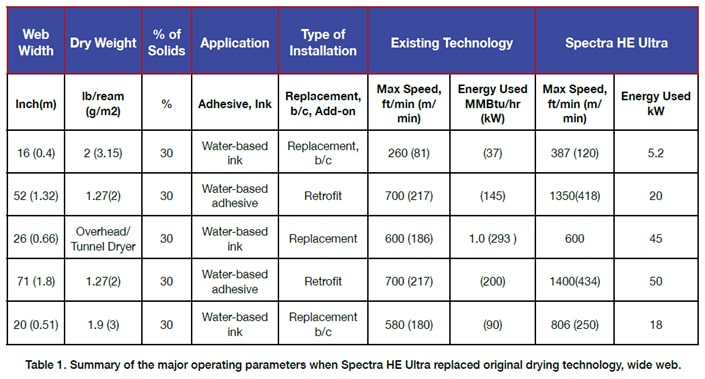

Highlights of Early Commercial Installations of Spectra HE Ultra

2013—2015

Spectra HE Ultra drying system as a complete replacement

A US based specialty food packaging company has installed and put into operation a Spectra HE Ultra drying system as a complete replacement of its existing system. The HTI drying system measured 45″ wide and 4 ft web long. The total installed power of the HTI system was 120 kW. As a result of the installation, two 100 kW IR blocks and a 2 million BTU/hr (586 kW installed power) convective, natural gas-powered dryer totaling 50 ft in length was turned off and removed. Customer freed up approximately 500 ft2 of floor space and increased production throughput by 30%. The quality of the finished product improved as well.

Booster station for a wide web rotogravure press

HTI has completed installation and commissioning of a booster station for a wide web rotogravure press. The unit will increase throughput of a cold seal and water-based pressure sensitive adhesive application. Complete startup and optimization of the process took six hours. As a result, the customer has awarded HTI another contract for a similar application.

Drying systems for a US based OEM of paper converting machinery

HTI has been awarded a contract on the delivery of six complete drying systems for a US based OEM of paper converting machinery. The award was based on successful customer paid trials at HTI’s facility in Atlanta.

HTI’s Spectra HE™ Ultra Designed into Major OEM Printing Press

HTI and the patented Spectra Ultra HE technology have been selected for inclusion in a new wide web printing press under construction by a European OEM supplier. The unit will be operational in the first quarter of 2016 with a US based converter. Dr. Jason Lye, CTO of HTI, remarks, “we see this as a significant milestone for the technology and the evolution of the company. The system has been recognized by both a tier 1 OEM and a globally active packaging converter for delivering throughput capacity enhancements not found in any other solution on the market today.”

2016 – HTI’s Spectra HE™ Ultra Designed into Major OEM Printing Press

HTI and the patented Spectra Ultra HE technology have been selected for inclusion in a new wide web printing press under construction by a European OEM supplier. The unit became operational in 2016 with a US based converter. The system has been recognized by both a tier 1 OEM and a globally active packaging converter for delivering throughput capacity enhancements not found in any other solution on the market today.” HTI sees this as a significant milestone for the technology and the evolution of the company.

2016-2017

HTI’s Spectra HE™ Ultra Designed into Major OEM Printing Press

HTI and the patented Spectra Ultra HE technology have been selected for inclusion in a new wide web printing press under construction by a European OEM supplier. The unit became operational in 2016 with a US based converter. The system has been recognized by both a tier 1 OEM and a globally active packaging converter for delivering throughput capacity enhancements not found in any other solution on the market today.” HTI sees this as a significant milestone for the technology and the evolution of the company.

EU installation on the coating line of the producer of coated products on non-wovens

2018

Several installations of complete drying systems (core technology) for the production of 3D products

2019-2020

Installation of drying system in the pharmaceutical industry